Warehouse racking is a vital ingredient in efficient storage administration, letting companies to improve Room, increase accessibility, and increase productivity within their amenities. With numerous racking techniques available, warehouses can successfully organize and retailer resources based on their distinct requires, from little products to bulk items. Deciding on the proper racking program not simply just maximizes storage capability but also guarantees worker basic safety and clean operations.

Forms of Warehouse Racking

Quite a few sorts of racking devices is usually utilized in warehouses, Every with unique rewards personalized to various storage demands:

Selective Pallet Racking: This could be the most popular racking method, delivering direct access to each pallet. It’s extremely adaptable, that makes it like minded for warehouses which has a superior turnover of varied goods. Selective racking maximizes accessibility, even though it won't be as space-effective as other methods.

Push-In/Push-Via Racking: Designed for large-density storage, travel-in racking permits forklifts to get in the racking process to maintain and retrieve pallets. It’s perfect for storing extensive quantities of similar parts of a last-in, 1st-out (LIFO) procedure. Drive-via racking, alternatively, follows a primary-in, initially-out (FIFO) system and can also be great for stock rotation.

Cantilever Racking: Best fitted to check here storing lengthy, cumbersome products like pipes, lumber, and metal rods, cantilever racks supply open fronts that simplify loading and unloading. They in many cases are employed in development and production amenities the place very long resources call for versatile storage.

Thrust Back Racking: This system operates around the series of nested carts that roll along rails, making it possible for pallets being stored two to 6 deep. It’s a highly effective, high-density Option for items that don’t need immediate retrieval, operating over the LIFO system.

Mezzanine Racking: By including yet another as well as third amount using a warehouse, mezzanine racking effectively doubles or triples accessible ground House with out growing the dwelling itself. This system is great for maximizing vertical Area.

Great things about Helpful Warehouse Racking

An productive racking technique considerably enhances warehouse operations by optimizing Room utilization, increasing access, and reducing retrieval moments. This prospects to raised stock administration, as items are very easy to get at and organized, which minimizes labor charges and boosts productiveness.

Racking programs also promote protection by structured and secure storage. Adequately intended racks lessen the possibility of accidents, guaranteeing a secure and secure atmosphere for the two employees and inventory. Additionally, very well-maintained racking units minimize injuries to stored merchandise, improving stock lifespan.

Selecting the Right Racking Process

Choosing the correct racking program is dependent upon elements like offered Room, inventory variety, turnover level, and spending budget. A radical evaluation of storage desires and operational movement allows in deciding upon a racking process that supports streamlined workflows and maximizes warehouse effectiveness. Effectively carried out, warehouse racking is surely an financial commitment that is smart in Area personal savings, protection, and extensive-time period efficiency.

Bug Hall Then & Now!

Bug Hall Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Destiny’s Child Then & Now!

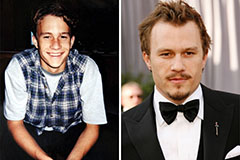

Destiny’s Child Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!